Web Based Remote Monitoring

Reliable Web based solutions for monitoring the condition or status of remote assets no matter where you or they are located.

Read more...

Reliable Web based solutions for monitoring the condition or status of remote assets no matter where you or they are located.

Read more...

SIL rated alarms systems, wireless telemetry and web based inventory tracking systems. Connects to your existing tank gauging.

Read more...

Advanced proven Impressed Current Cathodic Protection Systems incorporating Remote Monitoring and Control. New or retrofit existing sites.

Read more...

Specialised monitoring systems for Radiological environments including

nuclear power stations, storage facilities, PET

Centres etc.

Read more...

Real time energy, water, gas, air and/or steam monitoring for industry, commercial buildings and campuses. Meets reporting standards and reduces cost.

Read more...

Remote Temperature monitoring systems tailored for pharmaceutical and food industry applications from laboratories to warehousing. Meets reporting standards.

Read more...

Process Alarm Systems to IEC61508 and Event recording to sub-millisecond resolution making plants safer and reducing downtime.

Read more...

Upgrade your legacy alarm systems to current safety standards with minimum plant disruption. Custom solutions to suit individual needs.

Read more...

Data2Desktop provides an end-to-end solution to your remote

monitoring needs. Data2Desktop relieves you of the technical

complexities of implementation, with rapid low risk deployment.

Turn your organisation into a Real Time Enterprise within days.

more...

Remote Monitoring Specialists

Instrument PSUs

Priced to perfection

DIN Rail mounted

All Round Protection

Adjustable 24Vdc o/p

Home > Press Release

FOR IMMEDIATE RELEASE

The iron and steel industry has many critical temperature monitoring applications with the potential to cause or inflict tremendous loss if not monitored and controlled. Compatibility of the front-end temperature measuring system with a variety of supervisory systems is important.

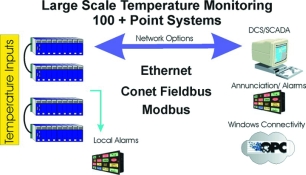

Omniflex offers a high-density temperature monitoring system catering for hundreds of temperatures at once using Maxiflex. No multiplexing and no rotary switches. Temperature inputs may be any 3-wire RTD or thermocouples and are configurable for an RTD or thermocouple type. Cold junction compensation and linearisation are all standard features.

Alarms and alarm annunciation

Each temperature input has four soft alarm setpoints allocated to it. Setpoints are configurable via the diagnostic/configuration tools or via scada or DCS. Setpoints can be mapped to physical outputs to provide alarm and trip functionality or simply read from the scada.

Program-less environment

Maxiflex provides a program-less environment for data acquisition. The system is simply configured using Windows-based tools for the temperature input type and setpoints if required. No application programs are required, the temperature inputs are scanned automatically and are made available to scada or DCS via a data interchange table in the Maxiflex CPU. Temperature can be represented in degrees Celsius or Fahrenheit selected by the user.

Local area network connections and supervisory systems

Networking on existing twisted pair cabling in the plant makes for easy retrofitting to difficult areas of a plant. Multidropping up to 126 devices along a single twisted pair cable will provide the capacity a total 2016 temperature channels on a single twisted pair cable. Ethernet gateways to supervisory systems are available and OPC servers allow all compatible scada packages to acquire the information from Maxiflex field devices. Supervisory systems can then use the data for pro-active plant management.

Cost-effective solutions and benefits

Maxiflex provides significant cost savings to high-density temperature measurement, with prices more competitive than hockey puck solutions for monitoring, the ability to integrate easily into supervisory and alarm/trip systems makes Maxiflex an unbeatable option. System additions are trivial and require minimal configuration to commission being measured in hours compared with days on conventional systems and thus passing on the savings to the end user.

Integration to local HMIs

HMIs can be used with Maxiflex to provide in-plant monitoring data to operational staff. Functionality of the system is varied and tailored to the application's needs. This is easily delivered by Maxiflex and a variety of local area network communications solutions including Ethernet to get the information back to supervisory systems. Local alarm and centralised alarm indication can be implemented with ease. Integration into Windows operating systems via OPC servers gives access to most scada packages on the market.

Some larger applications

* Boilers and boiler skin temperatures.

* Kilns and rotary kilns.

* Reactor/cracker temperature monitoring.

* Plastics moulding.

* Furnace monitoring.

* Temperature profiles and curing.

* Pump station motor winding and bearing temperature monitoring.

* Power station temperature monitoring.

Building upon the 35-plus years of experience in the field of alarm and events monitoring instrumentation for industry, Omniflex continues to provide solutions for many plant applications such as temperature monitoring.

Back to PR Listing

For further information on this press release please contact sales@omniflex.com

Product Ranges