Products > Process Automation Controllers

|

MAXIFLEX

Process Automation Suite |

|

Specialised solutions for

Distributed Process Control, Remote I/O Systems, RTU's, Alarm and Event Management,

and Signal Conditioning. |

|

|

|

FEATURES

- Modular and Scaleable "Buy what you need"

- Graphical User Programming

- IEC61131 Programming Languages

- Integrated Remote I/O sub systems

- Program-less Data Acquisition

- Powerful Built in Telemetry Functions

- Integrated Networking Architecture for Ethernet, Conet, Modbus

- OPC Servers for Windows Applications

- Easy SCADA and DCS access

|

|

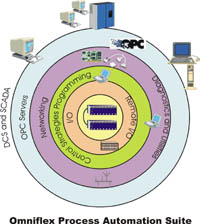

Maxiflex Process Automation

Suite The Process

Automation Suite provides an easy to use, cost effective and expandable

process control system. Integrated Control Software utilizing IEC61131

standard software languages, Data acquisition, Telemetry, Remote I/O

systems capability and the ability to incorporate and integrate existing

hardware systems makes this Omniflex Solution a System Integrators dream.

Modular, "Buy only what you need"

The Process Automation Suite is a modular system comprises the

following elements:

- IEC 61131 Control Strategy Programming Environment with a Windows

based PC Workbench

- The Maxiflex Process Automation Controllers Series and associated

I/O Hardware Platform

- The Maxiflex Flexible Networking Environment and Networking

hierarchy.

- The Maxiflex Remote I/O Systems capability

- Under the bonnet Data Acquisition and Telemetry functionality

- Integrated Alarm and Events Services(Date and Time Stamp Queue)

- OPC servers for a variety of Network Protocols including Ethernet.

IEC 61131 Workbenches Control Strategy Programming

The WorkBenches are price structured according to I/O

capability, with a range from 32I/O to unlimited. This allows the user to

pay according to the scale of the system. The workbench is a once off cost

and can be used with many CPUs. The workbenches are Windows operating

systems based.

Wide choice of programming languages

- Ladder

- Function Block

- Flow Chart

- Sequential Function Chart

- Structured Text

- Instruction List.

Maxiflex Process Automation Controllers

The PAC is based on the Maxiflex P3 CPU platform. The Maxiflex Process

Automation Controllers (PAC) run the IEC 61131 Control Applications and

are available in a number of variants to suit network preferences.

- Ethernet (with Modbus TCP)

- Ethernet (Conet)

- Modbus

- Conet/c

- Conet/m (Packet Radio Protocol)

This provides a flexible Network environment satisfying most networked

applications and plant topologies. Process Control Applications invariably

involve the following functionality for effective implementation.

- Interlock Controls

- Analogue Signal Processing

- Control Algorithms - including PID with Auto-tune

- Network Communications

- Alarm and Events Monitoring

- Date and Time Stamping at source for Sequence of Events monitoring

- The ability to service Windows based SCADA systems.

The PACs deliver all the above functionality on the standard platform.

Remote I/O Systems

Maxiflex is endowed with the ability to implement hierarchical networks

with transparent linking from lowest to highest level and vice versa. The

ability to configure seamless routing from Ethernet to a fieldbus network

like Conet or even a packet radio system provides system integration tools

few can compete with. Redundant communications can also be simply

implemented using modular applications. Field I/O can be collected easily

with Analogues Inputs such Temperature being accepted directly along with

a wide variety of other analogue and digital inputs and outputs.

Integrating Third Party devices

Maxiflex has direct serial inputs for which protocols can be developed to

integrate other devices in the Omniflex Remote I/O system. Devices such as

Analytical Instrumentation can be integrated into the system. Device

protocols are developed and downloaded to Network Interface Modules which

integrate the foreign device into the Maxiflex Network System.

Flexible Integrated Applications and Services

The Process Automation Suite offers many "under the bonnet" features like

date and time stamped events, Telemetry, Auto I/O Scanning which are all

standard offerings.

When combined together within a Control System the flexibility of the

system becomes apparent, allowing the independent delivery of functionally

different services all on a single system.

|

|

The complete Solution:

|

Download

System Brochure:

Click here

|

Whether your application

includes:

- An Ethernet backbone for plant wide

data acquisition

- An

existing plant-wide Distributed Control System

- A standardised PLC control systems

strategy

|

- Distributed

Systems to reduce cabling

- Redundant Systems

to minimise risk

- Critical Sequence

of Event Recording to trace faults requiring time-stamping at

source.

|

| MAXIFLEX

with CONET networking technology

provides the Total Solution |

|